The group of liquid thixotropic additives represents a class of unique rheology additives used for a wide variety of rheology properties due to their mode of action and ease of handling.

Liquid thixotropic additives are suitable for a very wide polarity range from aqueous to non-polar aliphatic systems. They can be used in both solvent-borne and solvent-free systems. Due to their liquid, low-viscous delivery form, they are easy to handle and can thus be incorporated into the final system by stirring in as a post-additive. Dosing under stirring conditions that ensure a fast, uniform distribution of the additive is usually quite sufficient to achieve the desired rheological effect. Strong shear forces or even temperature activation, as required for many other rheology additives, are not necessary.

The liquid thixotropic additives are mainly characterized by a pronounced structure formation in the low shear rate range. While shearing, they exhibit a strong shear thinning effect with a subsequent time-dependent recovery of the structure (thixotropy). The speed of the structure build-up depends on the additive dosage and the solids content of the formulation (the higher, the faster). The results are excellent storage stability, ideal anti-settling behavior and improved sag resistance. The low application viscosity ensures optimal atomization during spray application, good substrate wetting and good leveling. A particular advantage of this additive class is its pronounced elasticity, which results in good storage stability/anti-settling behavior even at low viscosity, e.g. in automotive coatings.

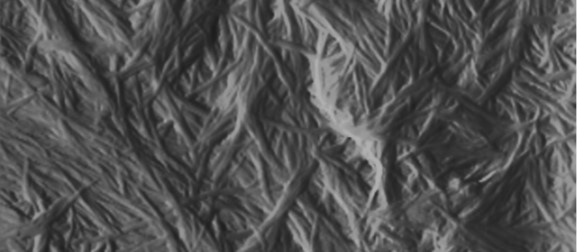

Urea compounds have functional groups that are able to form a three-dimensional network via hydrogen bonds. Such a network is reversible and can be used for rheology modification, such as viscosity adjustment. Naturally occurring urea can form hydrogen bonds, but its structure makes it incompatible in many substances. By suitable chemical modification, organic groups can be attached to the urea unit, resulting in organically modified ureas. Depending on the type of organic modification, the polarity and thus the compatibility can be adjusted over wide ranges, making appropriate modifications suitable for aqueous to nonpolar hydrocarbon-based systems. This is a relevant factor when it comes to tailoring the structure of a urea-based rheological additive for a specific polarity range.

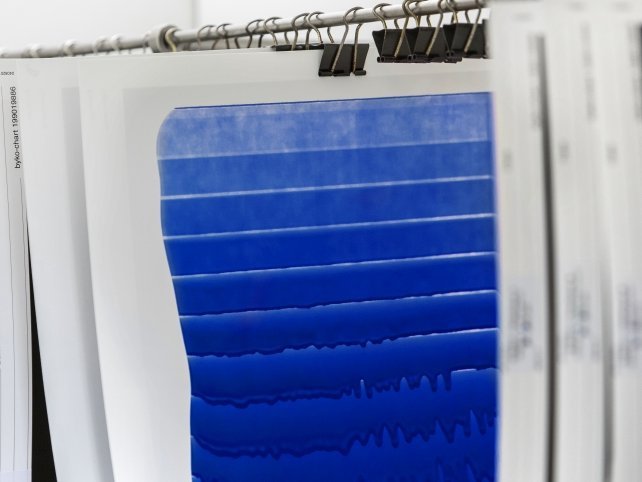

The mode of action of organically modified ureas is based on a precisely adjusted balance of solubility and insolubility: As an additive, the organically modified urea is supplied as solution in a suitable carrier medium, and the additive is therefore low in viscosity, pumpable, easy to dose and easy to handle. When the additive is used in an application system, microscopic crystalline particles are formed in situ that are so small that they have no effect on the gloss of the system.

These tiny crystals build up a three-dimensional network among themselves via the hydrogen bonds described. Since only the urea crystals are involved in this network formation, their interaction is generally independent of other components of the formulation such as binders or pigments. This distinguishes urea-based rheology additives from those that require specific interaction with other components of a formulation (such as associative thickeners interacting with the binder or wetting and dispersing additives with pigments and fillers). The interaction is also usually independent of factors such as pH value or the presence of various ions. Therefore, urea-based additives can also be successfully used to thicken acids, alkalis and salt solutions.

The formation of a reversible network via hydrogen bonds leads to a strongly thixotropic flow behavior: If the network is destroyed by force, the reorientation of the urea structures takes time, which explains the time-delayed rebuild of the network and thus the viscosity.

In addition to the viscosity, the formation of the three-dimensional network also has an influence on the viscoelastic properties. By increasing the elastic components, organically modified ureas are also suitable for setting a yield point and for achieving anti-settling properties, even without generating a strong increase in viscosity. The balance between viscosity increase, film thickness and anti-settling effect can be controlled by the dosage of the additive. Organically modified ureas can also contain other functional groups in addition to the urea groups. For example, urea-urethanes contain combinations of urea and urethane functions. Polyureas represent a subgroup of organically modified ureas that have longer molecular sequences with urea units.

On this website we use cookies and similar functions to process end device information and personal data. The processing is used for purposes such as to integrate content, external services and elements from third parties, statistical analysis/measurement, personalized advertising and the integration of social media. Depending on the function, data is passed on to up to 9 third parties and processed by them. This consent is voluntary, not required for the use of our website and can be revoked at any time using the icon on the bottom left.