Wesel, May 29, 2024 – Specialty chemicals manufacturer BYK is providing its customers in the thermoplastics industry with two innovative PFAS-free product solutions that master many current challenges in the production of films, pipes, profiles, fibers and much more. BYK-MAX P 4109 and BYK-MAX P 4110:

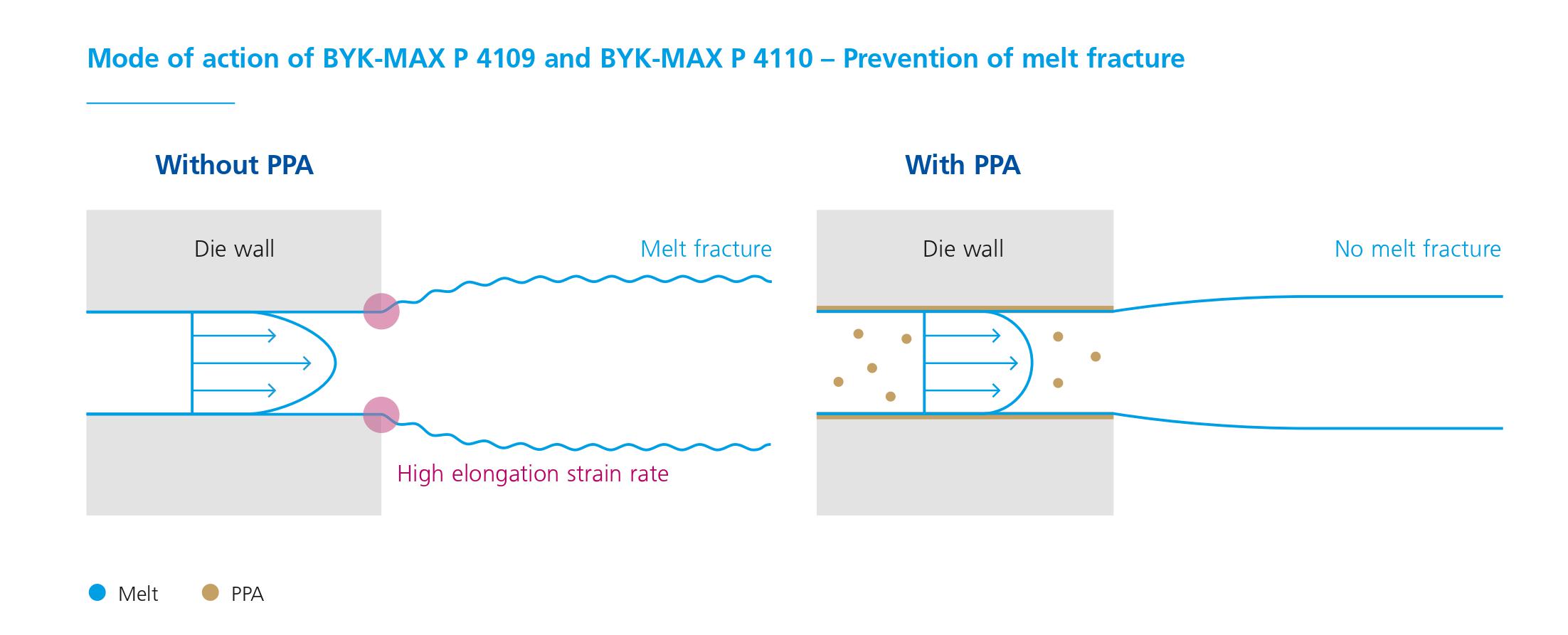

When processing polyolefins, high shear forces, temperatures and friction sometimes occur in the machines, leading to melt fracture or die build-up. In order to prevent these undesirable side effects and optimize production, fluorine-containing processing aids have often been used to date to ensure good throughput and defect-free finished parts. However, there are currently international legal initiatives to restrict the use of fluoropolymers (PFAS). BYK was quick to develop alternative additives that are PFAS-free and still have the usual positive effect on the process and result.

With BYK-MAX P 4109 and BYK-MAX P 4110, two new polymer processing aids (PPA) from BYK are now on the market that meet these requirements exactly: They are PFAS-free and at the same time allow a high production speed while preventing melt fracture and reducing die build-up which leads to less maintenance and therefore shorter downtimes.

The rapid effectiveness of the two additives cuts long rinsing times and allows fast product changes. In addition, both products are thermostable and are easy to handle.

Press Releases | May 29, 2024

BYK is a leading global supplier of specialty chemicals. The company’s innovative additives and differentiated solutions optimize product and material properties as well as production and application processes. Amongst other things, BYK additives improve scratch resistance and surface gloss, the mechanical strength or flow behavior of materials, and properties such as UV- and light stability or flame retardancy. In the field of quality assurance, BYK’s measuring and testing instruments serve to effectively assess appearance and physical properties.

The company’s customers include manufacturers of coatings and printing inks, plastics, adhesives and sealants, as well as cleaners, floor coatings, and lubricants. BYK additives are also successfully used in the construction chemistry, oil and gas, and foundry industries.

BYK has a global network of subsidiaries and operates production sites in Germany (Wesel, Kempen, Schkopau, Moosburg, Geretsried), the Netherlands (Deventer, Denekamp, Nijverdal), and the UK (Widnes), in the USA (Wallingford, Chester, Columbia, Earth City, Gonzales, Louisville, Pittsford), and in China (Shanghai, Tongling).

The company is part of the ALTANA Group and employs a workforce of more than 2,500 people worldwide.

On this website we use cookies and similar functions to process end device information and personal data. The processing is used for purposes such as to integrate content, external services and elements from third parties, statistical analysis/measurement, personalized advertising and the integration of social media. Depending on the function, data is passed on to up to 9 third parties and processed by them. This consent is voluntary, not required for the use of our website and can be revoked at any time using the icon on the bottom left.