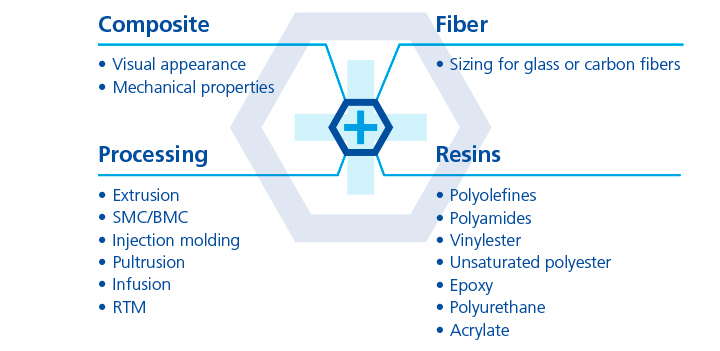

To fully utilize the potentials of advanced composites and optimize their manufacture, the use of special additives of BYK is extremely beneficial.

Wind power is one of the key technologies of our time – it has already become an indispensable medium in the worldwide energy industry. In view of the limited availability of raw materials and more ambitious climate objectives, the significance of this alternative source of energy is set to increase in the future. With its high-quality plastic additives, BYK is making a considerable contribution towards increasing the performance values of wind turbines and thereby further boosting the market development of this steadily growing global sector.

For example our coupling agents from the C-8000 series offer a number of key advantages, which breathe new life into the development of highly efficient wind turbines, as they enable:

The BYK advanced composites team offers you:

Wind energy

Wind energy  Marine construction

Marine construction  Sports/leisure

Sports/leisure  Automotive

Automotive  Aviation and aerospace

Aviation and aerospace

Coupling agents for thermoplastic composite materials

Coupling agents for thermoplastic composite materials

SCONA modifiers

Coupling agents for thermoset composite materials

Coupling agents for thermoset composite materials

BYK-C series

Rheology additives

Rheology additives

Thix boosters, solid thixotropes

Additives for glass-fiber sizing

Additives for glass-fiber sizing

AQUACER emulsions

Processing additives

Processing additives

BYK-P series

Modified clays

Modified clays

Reinforcing fillers

Additives for fiber wetting

Additives for fiber wetting

BYK-P 9920, BYK-9076

BYK-C 8013 is a solvent-free, polymeric coupling agent for improving the mechanical strength of carbon-fiber-reinforced, radical-curing systems, and it is the world’s first coupling agent for carbon fibers.

It is used in vinyl esters and unsaturated polyester resins that are processed to composite parts using carbon fibers. The cross-fiber strength is greatly improved, making far greater design freedom possible.

BYK-C 8013 increases both the transverse tensile strength and the flexible strength of the composite by means of improved fiber-matrix bonding. The chemical structure of the additive provides simultaneous adhesion to the fiber and to the resin matrix. This unique property makes changes in the component design possible, and it enables particularly durable components to be manufactured. Especially in hot-curing processes such as SMC/BMC, pultrusion, prepreg or RTM, BYK-C 8013 brings about increases in strength of up to 70 percent.

The reactive additive can be introduced to the size during fiber production or to the resin shortly before processing. In subsequent, so-called “second sizing”, BYK-C 8013 can, for example, be applied to the fiber in a spraying process, without the need to remove the first sizing beforehand.

In order to exploit the full potential of modern composites based on thermoplastics or duroplastics, the use of special additives provides great benefits. They are even used in starting raw materials for component manufacturing. For example, in sizing they are incorporated to improve processing or bonding of the fibers to various matrix systems. When directly used in resins, additives can modify a multitude of properties. In the finished formulation, they can significantly improve or, depending on the process, even make some processing properties feasible. Finished components have better properties or surfaces if additives have been used.

As one of the world’s leading supplier of plastics additives with longstanding experience in the field of composites, BYK is your partner, working together to develop the best technical solution.

On this website we use cookies and similar functions to process end device information and personal data. The processing is used for purposes such as to integrate content, external services and elements from third parties, statistical analysis/measurement, personalized advertising and the integration of social media. Depending on the function, data is passed on to up to 9 third parties and processed by them. This consent is voluntary, not required for the use of our website and can be revoked at any time using the icon on the bottom left.